Relied On Tahoe Instrument Cluster Repair Professionals: Bring Back Gauge Precision

Relied On Tahoe Instrument Cluster Repair Professionals: Bring Back Gauge Precision

Blog Article

Ultimate Resource for Advanced Automobile Instrument Cluster Repair Service Strategies

In the world of modern vehicle maintenance, the ins and outs of tool collection fixing stand as a vital facet of guaranteeing the ideal functioning of a car (tahoe instrument cluster repair). As modern technology advances, so do the intricacies of these important parts, requiring a detailed understanding of sophisticated repair service strategies. With a myriad of possible problems that can develop within instrument clusters, having a trustworthy source that uses extensive assistance on troubleshooting and correcting these challenges becomes paramount. By exploring the devices called for, typical issues experienced, and step-by-step fixing techniques, one can outfit themselves with the understanding needed to navigate the detailed globe of car instrument cluster repair with self-confidence and precision.

Importance of Advanced Instrument Cluster Repair

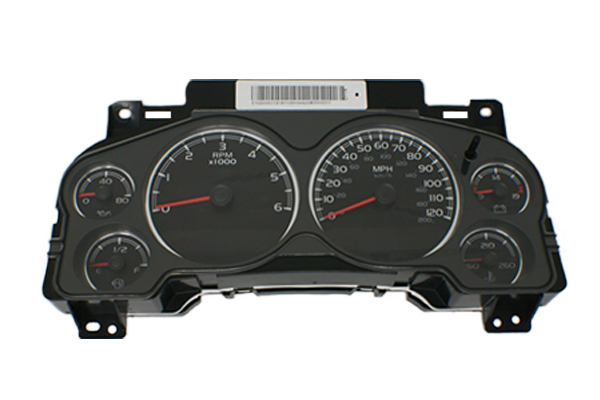

Understanding the significance of innovative tool cluster fixing is necessary for maintaining the capability and accuracy of contemporary lorry systems. The instrument collection acts as the hub of details for chauffeurs, showing critical information such as rate, fuel levels, engine temperature, and cautioning indications. With the improvement of modern technology, instrument clusters have actually advanced to incorporate complicated digital components and digital screens, making repair work extra intricate and specialized.

Appropriate repair service and upkeep of the instrument collection are crucial for making sure the safety and security and efficiency of the lorry. Issues with the instrument cluster can result in inaccurate analyses, malfunctions in essential systems, and safety dangers on the roadway. Advanced tool collection fixing strategies entail detecting digital mistakes, recalibrating sensors, and reprogramming software application to bring back ideal performance.

Tools and Devices Required

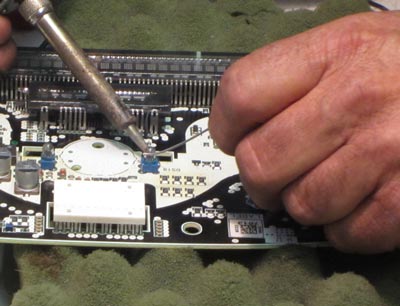

To successfully resolve the detailed repair requirements of modern-day lorry tool collections, a specialized collection of tools and equipment is necessary. A few of the trick devices required for advanced auto tool collection repair service include precision screwdrivers, trim elimination devices, soldering equipment, electronic multimeters, and analysis scanners. Precision screwdrivers are essential for disassembling the collection without triggering damage. Cut elimination tools help in securely spying off bezels and panels. Soldering devices is required for fixing busted connections or replacing parts. Digital multimeters are utilized to measure voltage, connection, and resistance during diagnostic procedures. Analysis scanners are vital for recognizing and fixing digital problems within the instrument cluster. Additionally, having an excellent high quality soldering iron, desoldering pump, and solder cord is essential for carrying out complex soldering work. Appropriate lighting, a magnifying glass, and a tidy workspace are likewise vital for making certain precision and precision during fixings. By having these specialized devices and equipment on hand, professionals can successfully detect and solve complicated concerns in car tool collections.

Usual Issues and Solutions

Several typical problems often encountered in car instrument clusters can be efficiently solved via targeted remedies. One widespread issue is malfunctioning gauges, which may result from a malfunctioning stepper electric motor. To resolve this, changing the stepper motor can restore accurate gauge analyses. An additional usual concern is flickering or dark lights on the instrument collection (tahoe instrument cluster repair). This can typically be connected to a defective bulb or poor links. By replacing the light bulb or ensuring safe links, the lighting concern can be conveniently remedied. Furthermore, a malfunctioning odometer or display screen is a frequent concern. This can be as a result of a faulty screen unit that requires to be changed to bring back proper functionality. Intermittent power or complete failure of the tool cluster might stem from a blown fuse or electrical wiring problem. Monitoring and changing the fuse, as well as examining the wiring for any kind of damages, can aid fix these power-related problems efficiently. By recognizing these common issues and using the ideal options, vehicle tool cluster functionality can be brought back effectively.

Step-by-Step Repair Work Overview

A methodical technique to fixing and diagnosing car instrument collection concerns is important for attaining accurate and effective results. To begin the repair service procedure, the very first step is to page very carefully evaluate the instrument cluster for any visible damages such as burnt-out light bulbs, fractured screens, or loosened links. Next off, it is crucial to carry out an analysis check making use of specialized equipment to identify any type of underlying electronic problems. When the trouble locations are determined, the repair can commence by either replacing faulty components, repairing damaged circuitry, or recalibrating sensors.

Tips for Precautionary Upkeep

After performing a thorough analysis check and completing needed fixings on the automobile tool cluster, implementing normal preventative maintenance steps is essential to make certain long-lasting capability and optimum efficiency of the automobile's vital assesses and signs. To begin, it is important to routinely evaluate the tool cluster for any type of indicators of wear, such as fading screens or malfunctioning lights.

Additionally, upgrading the software program of the instrument collection when required can make certain compatibility with any type of new attributes or systems in the car. It is you can find out more also a good idea to follow the maker's recommended maintenance routine and standards for the tool collection to maintain its long life. By incorporating these preventative maintenance ideas into your regular automobile care, you can assist expand the lifespan and dependability of your vehicle instrument cluster.

Conclusion

Finally, innovative auto instrument collection repair strategies are important for keeping the functionality of contemporary lorries. By this post utilizing the appropriate devices and equipment, attending to usual issues, and adhering to a step-by-step repair guide, professionals can successfully repair and identify tool collection troubles. Implementing preventative maintenance strategies can assist lengthen the life-span of the tool collection and protect against future concerns from arising.

By checking out the devices called for, typical issues ran into, and detailed repair methods, one can furnish themselves with the understanding needed to browse the elaborate world of automobile instrument cluster fixing with confidence and precision.

A methodical approach to fixing and identifying automobile instrument cluster concerns is important for attaining exact and reliable results. By following this detailed overview carefully, car professionals can properly detect and repair tool collection concerns with precision and confidence.

In verdict, innovative car tool cluster repair work techniques are vital for maintaining the capability of contemporary vehicles. By making use of the proper devices and devices, resolving usual issues, and complying with a step-by-step repair work guide, service technicians can efficiently fix and detect instrument collection problems.

Report this page